Cangzhou, Hebei, China

Response Time: < 24h

Response Rate: 0%

Double Layer Trapezoidal Roof Tile Building Material Roll Forming Machine

Double Layer Trapezoidal Roof Tile Building Material Roll Forming Machine

| Model No.: XH840-850 | Brand: XINGHE | Place of Origin: China |

| Product name: Roof Sheet Formin... | After-sales Servic...: Online support | Color: Client's Request |

| Warranty: 12 Months | Roller material: 45#steel Chrome Pl... | Raw material: PPGI PPGL G... |

| Usage: Steel Construction | Cutting blade mater...: Cr 12 High Grade... | Shaft material: High Grade No.45 ... |

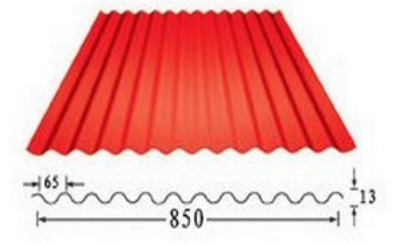

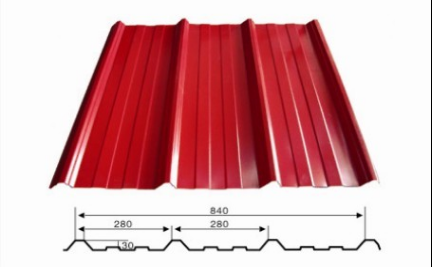

Profile drawing as below

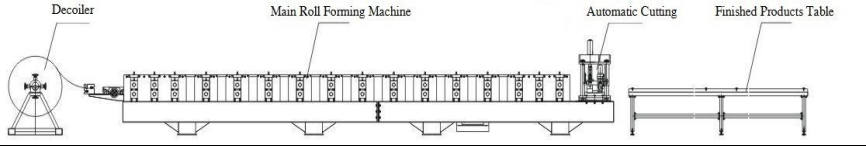

The work flow of machine

Part 1:5 ton Decoiler

|

Usage |

Support and uncoiling the coil |

|

Feature |

1. Brake system ensure the coil not disperse when facing critical situation. 2. Hand wheel can help the coil turning when needed. |

|

Work type |

Passive type |

|

Structure |

Steel channel for basic frame |

|

Loading capacity |

5 Tons |

|

Coil inner diameter |

Coil inner diameter |

Part 2: Main roll former

|

Feeding device |

Feeding the material into machine |

|

Roller shaft |

Shaft material:45# steel |

|

|

Shaft diameter: up layer: 75 mm down layer: 75 mm |

|

|

Tempering treatment to prevent deformed and improve hardness |

|

Roller material |

45# steel |

|

|

Chromed treatment, make the rollers more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life |

|

Roller station |

Up layer: 9 roller stations (corrugated roof sheet) Down layer: 11 roller stations (trapezoid roof sheet) |

|

Work speed |

Up layer: 0-20 m/min Down layer: 0-20 m/min |

|

Machine structure |

Steel plate welded structure |

|

Machine basic frame |

350# H steel welded with diagonal bracing inside |

|

|

The diagonal bracing can keep the machine in a high stability, ensure all the sides in the same horizontal level, to prevent the sheet shift left or right when forming |

|

Work power |

5.5kw |

|

Rolling spacer |

Anti rusty, chromed treatment |

|

Pull rod |

Anti rusty treatment |

|

Transmission |

By double chains with cover |

|

|

Noted: please fill the lube in case the chains getting dry |